Our approach to tool materials and tool performance is determined by our focus on increasing the competitive advantage of our customers through our tool materials. Based on this approach we have been developing tool materials that allow important advantages in terms of productivity and durability, design flexibility and the production of light weight components. We speak and feel tools, accompany them over their life and record their history and experience

The final component cost depends on the cost-effectiveness of many different aspects of the chosen tooling system: die material properties, die hardness, hardening methods and path, eventual surface treatment, die geometry, die cavity microstructure configuration, working temperature and other process parameters. Our vast experience in the application of our high performance tool materials has generated a large know-how in the most efficient usage of our tool materials for different applications according to the specific objectives of our customers. You can access our technical support service directly by sending an email to ae-fast@rovalma.com.

Our Process Optimization Services comprise:

Advise in the selection of die, mould and tool materials in accordance with the application requirements, the quality of the produced parts, the productivity and specific features of the production process, and the longevity of the high performance tools.

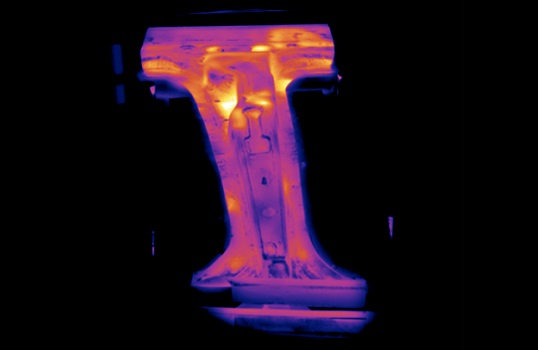

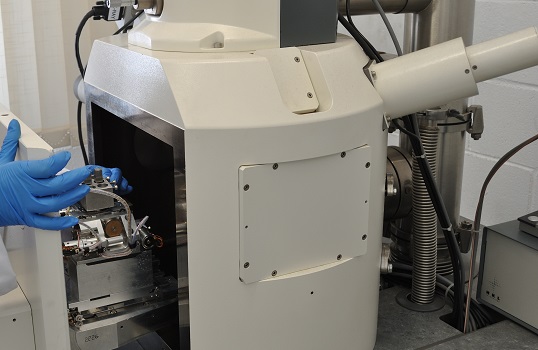

Advanced thermo-mechanical analysis of dies and tools during production conditions to optimize the setting of process parameters, achieve shorter cycle times and longer tool durability

Tailoring tool material properties to produce tailored components and complex geometries

Advise in advanced welding and surface treatment solutions

Other related technical services