Additive Manufacturing

Additive manufacturing (AM) is the process of joining materials to make objects from 3D model data, usually layer upon layer, and by means of a computer controlled laser as energy resource in the case of metal powder feedstocks.

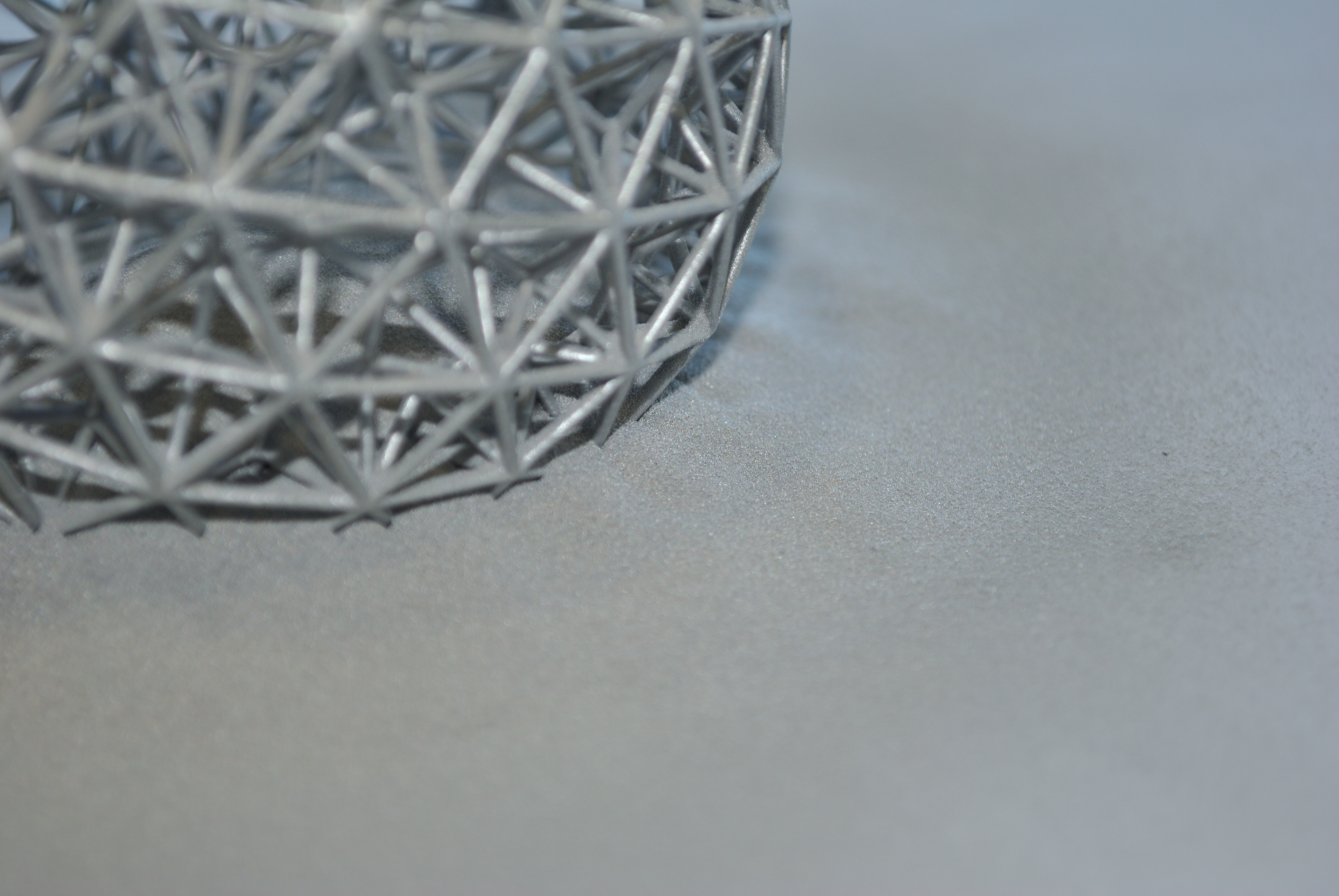

Unlike conventional subtractive manufacturing techniques, AM technologies create the product shape by adding successive layers of material with virtually no geometric limitations. AM techniques offer enormous opportunities to reduce the consumption of raw materials and to produce minimal waste by way of final or near-net-shape product manufacture.

In the area of tooling, high levels of geometric flexibility and accuracy can already be achieved with current AM technologies, which enables advanced cooling systems, and thereby complex and lightweight component design in many application sectors, such as in transport, packaging or the production of components for home appliances and the electronic industry. Also, important cost-savings through shorter cycle times, reduced production steps and simplified supply chains have been achieved in different application areas through the usage of additive layer manufacturing technologies. The associated reduction in energy and raw material consumption, be it in the manufacture of the tooling, or the production and usage of the resulting product are future key contributions to environmental sustainability and environmental footprint.

Chemical composition, particle size, shape and distribution, mechanical and thermal properties of the metallic powder play a key role in controlling the behavior of metallic powders during the AM process. The specific features of the powder directly affects the powder flowability, particle cohesion, inter-particle friction, the values of bulk and tap density, cleanliness, porosity, internal defects and homogeneity. All these parameters, together with the process parameters (e.g. laser power, scanning speed, hatching distance, layer thickness, among others), determine the thermo-mechanical properties and surface quality of the manufactured components.

ROVALMA, S.A. develops and supplies advanced metal powders for a variety of applications, such as for the usage in AM technologies, welding, thermal projection, metal injection molding, cladding, hot isostatic pressing, amongst others. Moreover, as a proven pioneer in technological innovation in the metallurgical field, ROVALMA, S.A. also provides strong technical and engineering support to its customers and cooperation partners in the different application fields for advanced metal powders.