Innovative Die Material Solutions for Die Casting by ROVALMA

Based on 40 years of experience in tool materials and on the know-how of our dedicated scientists and technicians in the development, production and application of tool materials, ROVALMA has generated breakthrough die material solutions for many engineering applications. For the manufacture and usage of die casting dies, ROVALMA provides a comprehensive material solution package of different die material grades to respond to the diverse technical requirements of the different casting processes and optimization criteria of die designers, manufacturers, users and component buyers.

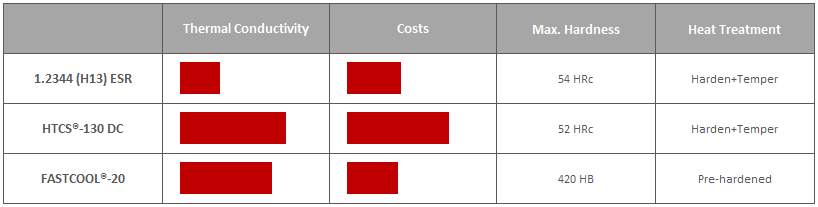

To fight against hot spots, porosity, slow cooling, long cycle times and other problems related to the slow cooling of conventionally employed die materials, ROVALMA invented and pioneered the application know-how of High Thermal Conductivity Tool Steels. Nowadays, two grades of theses tool steels are specially tailored for different die casting applications: HTCS®-130 DC and FASTCOOL®-20.

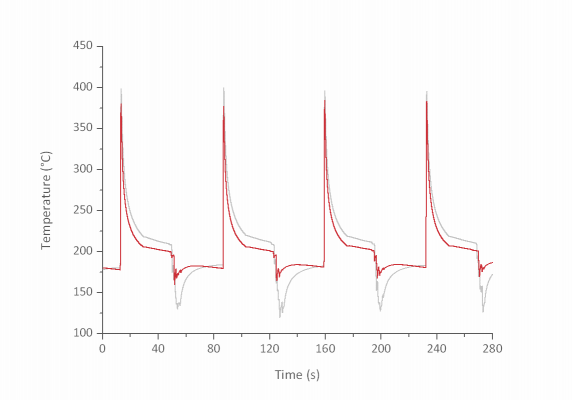

The thermal conductivity of these high performance tool steels is around twice that of conventional hot work tool steels. With these tool steels, ROVALMA offers a unique solution to fight against thermally related problems, in particular shrinkage porosity, slow cooling, shrinkage related dimensional deviations, and long solidification times. FASTCOOL®-20 is a revolutionary die cast steel pre-hardened to 400±20 HB, differing from conventional harden & temper die steels by offering a homogeneous property distribution from the surface to the core of the die, combined with high thermal conductivity. For die casters, both grades allow to increase productivity through higher production process stability (less hot spots, less soldering, better cooling), shorter cycle times, faster heating and cooling of the die and better component quality. FASTCOOL®-20 furthermore enables a considerable decrease in die manufacturing lead times. Component buyers appreciate the increased flexibility in component geometry (reduced thickness and more complex geometries) and reduced component cost and delivery times).

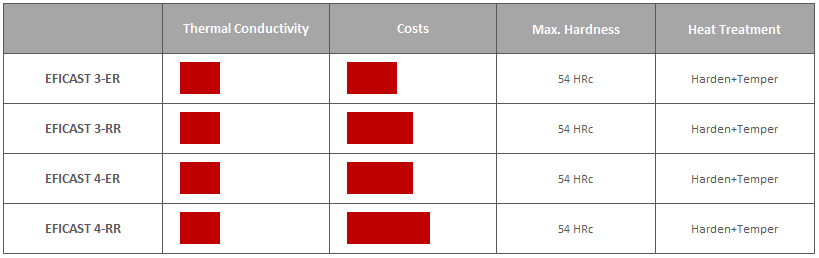

ROVALMA's EFICAST-3 and EFICAST-4 tool steel grades have been modified to provide the highest quality, high performance tool steel grade alternatives to the conventional tool steel grades EN/DIN 1.2343 and 1.2344. EFICAST grades are produced and refined by using the latest production technology for melting, forging and thermal processing to obtain the highest possible level of purity, isotropy, refined microstructure and fracture toughness. ROVALMA applies a comprehensive and strict quality control to ensure compliance with the highest quality standards for die cast materials, such as NADCA recommendations.