Innovative Material Solutions for Hot Stamping Dies by ROVALMA

Based on 40 years of experience in tool materials and on the know-how of our dedicated scientists and technicians in the development, production and application of tool materials, ROVALMA has generated breakthrough die material solutions for many engineering applications and also pioneered optimized material solutions for hot stamping dies.

Over the past decade, the technical requirements for hot stamping toolings have become clear. Given that the quenching rate and cooling capacity of the tool are key factors that determine the production cost and component quality, it is evident that very high thermal conductivity is required from the tool. As for tool durability, another important production cost contributor, high adhesive and abrasive wear resistance is required from the tool together with high resistance to cracking.

A decade ago, ROVALMA has invented a new hot work tool steel that features up to 60 W/m·K. with hardenability up to 52 HRc. Since then, several grades of this high thermal conductivity tool steel family optimized for different application requirements have been developed and provided to hot stampers to cover different technical and economic needs, such as tools for direct or indirect hot stamping, prototyping, small, middle and large production series, very high quenching requirements, limited tool construction times, blank type etc. In addition, ROVALMA’s HTCS®-230/233 grades for hot stamping toolings offer a further revolutionary feature as they can be hardened up to 50/52 HRc by a simple precipitation hardening (aging), which allows to considerably cut down the lead time for die construction and to enhance tool durability through a homogeneous distribution of the tool properties along the different tool sections. The following table shows essential properties in comparison to conventional hot work tool steels.

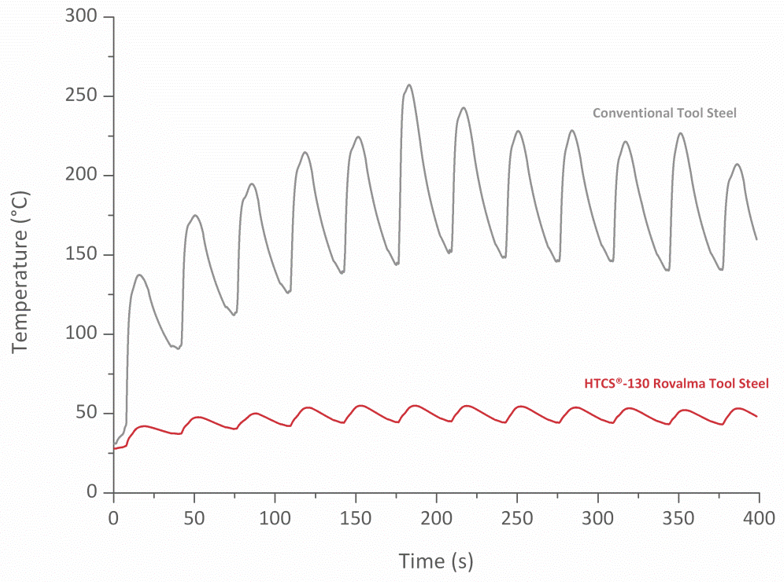

With these tool steels, ROVALMA offers a unique solution package to fight against thermally related problems associated to conventional tool steels, in particular, against long cycle times, slow quenching rates, hot spots, fast wear and premature-cracking, and related quality and process problems. The wearing of the tool is also related to the working temperature of the tool. For the same level of hardness, high thermal conductivity tool steels feature higher wear resistance because the working temperature of the tool is generally around 50-100°C lower than when using conventional tool steels with lower thermal conductivity, as can be seen from the case study graphic illustrated below for different cycles for the hot stamping of a Usibor blank. Considering the different technical requirements of a specific hot stamping process, the optimal tool material solution for a given hot stamping application should be customized not only in terms of tool steel choice, but also in terms of hardening options and machining and cooling design strategies. For this reason, ROVALMA offers its customers support in the selection of the right tool material considering these strategies and the technical specifications of each single project.